As the world accelerates towards net zero, demand is increasing for low-emission technologies like electric vehicles, solar panels and rechargeable batteries. At the heart of these innovations are critical minerals – including lithium, nickel and copper – which are essential ingredients needed to manufacture the clean energy future.

However, extracting these minerals from ore comes with significant challenges. Maximising critical mineral recovery must be balanced with reducing water use and managing mine tailings, all while keeping costs down.

Jord International is developing a solution to these challenges.

Partnering with the University of Newcastle Chief Investigator, Dr Peter Robinson, and supported by Trailblazer for Recycling and Clean Energy (TRaCE), Jord International has signed a $1.4 million R&D project to tailor their already successful ‘VIPER Dewatering Technology’ specifically to critical mineral recovery and waste mitigation.

From proven performance to scalable solution

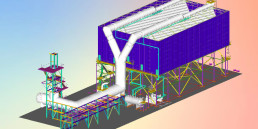

This new TRaCE project is advancing Jord International’s existing VIPER technology, a system that was designed in collaboration with the University of Newcastle’s Centre for Bulk Solids and Particulate Technologies. Led by Professor Craig Wheeler and Dr Peter Robinson, VIPER optimises the Horizontal Vacuum Belt Filter (HVBF) via the addition of vibration and compaction to the material. This system facilitates a cost-effective and scalable solution to dewatering fine and problematic mining materials. The VIPER system can be retrofitted or supplied new, offering a practical, low-cost pathway to cleaner, more efficient mineral processing.

With ‘VIPER 2.0 – Vibration Assisted Recovery of Critical Minerals’, Jord International will construct a bespoke pilot plant at the University of Newcastle’s Institute for Energy and Resources (NIER). Access to these facilities will enable the team to tailor the performance of their vibration and dewatering technology towards mineral recovery and optimise the technology across new applications for commercial deployment.

“This project aims to translate the significant benefits of the VIPER Dewatering Technology to the recovery of critical minerals and handling of mining waste products,” said Dr Peter Robinson. “Conventionally, mineral recovery utilises copious amounts of water. However, with the application of VIPER, we expect to see substantial savings in cost and water requirements.”

A core focus of the project will be to further develop the technology as a practical solution to the challenge of dewatering mining tailings. Traditionally, tailings (the residual waste left over after ore processing) are discarded in large storage dams which, if poorly managed, can pose a significant environmental and safety risk. By applying compression and vibration, the VIPER technology can be applied to the extraction of critical minerals from this waste while enhancing the dewatering process, yielding a drier waster material with the potential for dry disposal.

“The landscape of dewatering technologies has advanced significantly in recent years, driven in large part by Jord’s successful deployment of the VIPER technology,” said Sam Caldwell, VIPER Technology Manager.

“As a core element of our innovation strategy, we remain focused on the continued optimisation and enhancement of this platform to expand its applicability and amplify its operational impact. We are placing particular emphasis on addressing the evolving demands of the critical minerals industry, where efficient dewatering is essential to meeting production and sustainability goals.”

This technology has multiple benefits including:

- Supporting the reuse of water within the processing cycle.

- Reducing energy requirements and transport costs by producing a drier, safer material.

- Facilitating safer disposal methods of waste material in the form of dry stacking.

- Allowing for additional critical mineral recovery.

Ultimately, the VIPER 2.0 technology aims to increase critical mineral recovery by 5 per cent, reduce water usage by up to 10 per cent and lower the energy consumption of the entire process. This translates to gaining more value from existing resources and having less environmental impact, which is crucial for a circular economy.

Supporting a smarter minerals industry

As the demand for critical minerals grows, so too does the need for smarter ways to obtain them. With their VIPER technology, Jord International is forging ahead in developing innovative solutions to meet this demand responsibly. By improving the efficiency and sustainability of critical minerals recovery, this project offers a blueprint for a scalable solution to support global demand and reduce environmental impact.

“Our global mining clients increasingly seek innovative technologies that maximise value recovery across their operations, whether through the extraction of previously unrecovered materials, enhanced water reclamation or improved energy efficiency,” said Kevin Barber, Head of Resources Jord International. “At Jord, we remain committed to addressing these fundamental challenges by bridging academic best practices with practical, industrial solutions.”

“The end-users of our technology are the world’s leading mining operations, organisations at the forefront of the global energy transition. The adoption of advanced dewatering solutions plays a critical role in enabling sustainable mineral processing, ensuring the efficient use of water, energy, and resources necessary for a low-carbon future.”

TRaCE will support this project by providing essential funding and access to a network of industry experts and facilities. By leveraging TRaCE’s ecosystem, the project team will be able to optimise the VIPER technology across a broad range of applications. For more information on how you can get involved in the TRaCE program, visit www.trace.org.au or contact hello@trace.org.au

Other News

Jord opens office in Denver, USA

Jord is proud to open its new office in Denver, Colorado, to provide greater service and responsiveness to customers throughout the Americas.

The Two Essential Elements for Employee Engagement

Jord's Head of People and Culture discusses best practice HR initiatives to retain high performing engineers. Watch a short video.

NovaCell™ implemented at Industrial scale

A partnership between Jord International, Aeris Resources and the NSW Regional Government is financing the installation of the first industrial-scale NovaCell™ Demonstration Plant.

SWITCH2 WELCOMES NEW SHAREHOLDER JORD GROUP

Jord has invested in SwitcH2 BV to jointly finalize the design of the 300 MW Offshore Floating Ammonia Project

JordProxa and Vulcan Partnership

JordProxa and Vulcan Partner for Phase One of ZERO CARBON LITHIUM™ Project

2020 Outback tour

Foundation,Bush Heritage Australia

Jord’s 2020 tour was somewhat compromised by the ravages of Covid. Or so we thought.

Celebrating 10 Years; Jord and Bush Heritage Australia

Foundation,Bush Heritage Australia

This year marks a truly special milestone; the 10th Anniversary of the collaboration between Bush Heritage Australia and Jord.

Aminpro Exclusive Testing Partner NovaCell Chile

Aminpro, a leading metallurgical testing and consulting firm, is proud to announce its designation as the exclusive testing partner for Jord International’s groundbreaking NovaCellTM flotation…

Jord International partners with Orica to Reduce Particulate Emissions at Kooragang Island Ammonium Nitrate Plant

In August 2018, leading mining and infrastructure solutions provider Orica committed to reducing particulate matter emitted by its Kooragang Island ammonium nitrate plant.

Engineering modular process infrastructure for rare earths

The Australian Mining Review examines how the Jord Group is applying its engineering and delivery capability to the evolving requirements of Australia’s critical minerals value chain.

A Rising Sun

Mechanical completion milestone reached for battery chemical crystallisation plant

Trinidad methanol & DME plant commences commercial operation

Jord collaborated with Mitsubishi to deliver 2,000 tons of bespoke modular Dry Cooling systems to this plant

Jord’s Latest Can Do Award Winners

It's a new quarter and time to celebrate the success of our most recent Award Winners for their outstanding display of Jord’s 'Can Do' spirit.

Jord at SME MINEXCHANGE 2025

This year’s SME MINEXCHANGE truly felt like home for our local Denver team, led by our Vice President of the Americas, Oliver Whatnall.

Jord Appoints Matthew Marinovich as Head of Energy

Matt joins Jord with more than 20 years of experience in the chemical, equipment, and industrial services sectors, bringing deep expertise in gas processing and modular LNG systems.

Supporting colleagues through the COVID crisis

As the pandemic disrupts our lives in unprecedented ways, acts of kindness and care from colleagues make a huge difference.

Nurturing the Night Parrot

An arid patch of ground some 1,500 km north-west of Brisbane hit global headlines in 2013, with the exciting re-discovery of the Night Parrot, a nocturnal ground dwelling parrot previously thought…

Clear skies ahead for Newcastle

Orica is set to substantially reduce particle emissions from its Kooragang Island, Newcastle explosives facility

Jord funds establishment of Bintan Marine Protected Area

Jord is proud to announce its commitment to co-finance and support the establishment of a marine conservation initiative in Indonesia.

BHP awards Jord Supplier Innovation Program project

Jord International has been awarded the first contract from BHP under their Supplier Innovation Program Challenge that was launched in partnership with Austmine in 2020.

Jord Appoints Claire Jelbart as Head of Legal

Claire is a highly experienced executive leader, lawyer, and governance professional, bringing more than 20 years of experience in major projects and M&A across renewable energy, natural gas, LNG,…

A look back at 2021

Business,People & Culture,Foundation

With the COVID pandemic continuing, it was another big year for the Jord Group. Despite the uncertainty and challenges in business conditions, we managed to execute and deliver to our clients’…

Success out the back of Bourke

Foundation,Bush Heritage Australia

Bush Heritage's Greg Carroll showcased his photography skills when Jord staff visited the remote Naree Reserve

Milestone Moment: Jord Celebrates New Baroda Office Extension

Jord International is proud to announce the successful completion of our new office extension in Baroda, India.

Jord’s Can Do Award Winners

Let us celebrate the success of our most recent Can Do Award Winners.

A final ball cricket classic

Taking place at Perth’s picturesque Leeming Spartan Cricket Ground, the home side ultimately triumphed in Jord’s annual World Cricket Challenge, in fast-fading light and on the very last ball.

Omani CCPP commences commissioning

Commissioning works commence for Oman's latest power plant

Typhoon Yolanda, Philippines

In November 2013 super typhoon Yolanda – the strongest typhoon recorded in Philipino history – left at least 10,000 killed.

A warrior marks his 20th year at Jord

There has been no job site too far, no journey too long, no task too difficult and no hardship too arduous for Indonesian based Field Engineer Busra.

Century makers

Four more names have been etched into Jord’s 10 year service honour board. This brings the total of men and women, past and present, who have worked more than 10 years at Jord to over 100.

Congratulations to our December Can Do Award winners

This group was recognised for their outstanding commitment, problem-solving mindset and willingness to go above and beyond to deliver strong outcomes for Jord.

Clean Energy Cravens Peak Wilderness Queensland, Australia

Foundation,Bush Heritage Australia

Jord’s JET trust funded the installation of a 10 kW solar powered energy system to provide the necessary power that allows Bush Heritage residents and visiting scientists to conduct station…

Jord recognised by GE Vernova with Supplier Partnership Award

Jord is proud to be recognised by GE Vernova with their Supplier Partnership Award for Accountability.

Video link remote inspections

Watch to learn how we discovered remote inspections can be even more thorough than in-person reviews. We undertake remote inspections by video link, which involves a local Quality Control inspector…

Jord Energy Expands Global Footprint with New Office in Chennai, India

Jord Energy has officially opened its newest office in Chennai, India, marking a significant milestone in the company’s global growth strategy.

Recent Jord “Can-Do” award winners 2021

Jord recognises stand-out efforts from staff with quarterly Can-Do awards. Here is a selection of 2021 awardees.

Jord delivers energy efficient Topsides for Brazli FPSO

Jord Oil & Gas Systems b.v. is delighted to have played a part in delivering Yinson Production’s first FPSO

Clean Water Bon Bon Reserve, South Australia

Foundation,Bush Heritage Australia

JET funded a project to upgrade the water treatment and storage capability of the staff quarters.

Jord “Can-Do” award winners 2019

Jord recognises stand-out efforts from staff with quarterly Can-Do awards. Here is a selection of 2019 awardees.

Japan’s ever-expanding renewable energy drive

Jord is delighted to confirm its participation in the Wakayama Gobo Biomass Power Plant, located 120 km south of Osaka, Japan.

Ganesh Chaturthi

We’re an agnostic company, supportive of and curious about all peace-loving beliefs, religions and ideas.

Jord International welcomes new CEO, Greg Jones

Jord International (Jord) has appointed Greg Jones as CEO, commencing July 15

30 Year Milestone

Emilio Ambrogio spoke movingly when his 30 years at Jord were honoured at the recent Sydney office birthday celebration.

Jord’s humble beginnings in the 1970s

Jord Co-founder Phil Blundell says it doesn’t seem like 50 years since his business partner John Holden returned from the Racecourse Sugar Mill in Queensland with Jord’s very first order.

Back of Bourke

As a metaphor for a place far from anywhere, “back of Bourke” was coined for a reason.

Finding that work – life balance

It's good to see this "work - life" balance we hear about so often put into practice

Our Latest Can-Do Award Winners

The “can-do” attitude of our people is the reason Jord has achieved 50 years of experience and continues to grow

Jord International featured by HSBC Corporate and Institutional Banking and the AFR

As our global footprint has expanded, so too has the complexity of our operations and banking needs.

2022 Bush Heritage Working Bee

Foundation,Bush Heritage Australia

It was under a ancient reclining (but still thriving) walnut tree where Australia’s Bush Heritage, Tasmania’s Wilderness Society and The Greens Party were conceived, thanks to founder Bob Brown.

Celebrating International Women’s Day 2021

For International Women’s Day 2021, we celebrate all of the talented and dedicated women we are fortunate to work with and we invite four of them to share their personal experiences and advice about…

Jord commits $290,000 for marine conservation project

JET continues to get its feet wet, providing key support to a major marine conservation project off the east coast of Indonesia’s Bintan Island.

Annual Cricket Match

As part of Jord’s 50 year celebrations, our annual cricket match took place at Bowral’s stunning Glenquarry Oval.

Searching for Planigals

This fourth instalment of Jord’s annual Bush Heritage weekend involved 19 of us flying to its 60,000 hectare Carnarvon Reserve in central Queensland.

JordProxa selected for Vulcan Energy’s Lionheart Project

JordProxa selected as technology and equipment partner for Vulcan Energy’s Lionheart Project in Germany.

Habitat restoration in remote South Australia

Foundation,Bush Heritage Australia

Bush Heritage Australia purchased Boolcoomatta in 2006 and is painstakingly restoring the land to its original condition. A dozen Jord staff enjoyed a long weekend on the property, engaging in some…

Staying Ahead with Ideas

By feeding creativity and pushing boundaries, Jord has expanded its technology offering over the past 50 years.

Smiles all around

Hats off to Jord Malaysia's fabrication team, for completing a milestone event

Clean Water Nias, Indonesia

Jessie Salazar spearheaded a campaign for Jord to help give immediate assistance to people left homeless and destitute in the town of Tacloban after super typhoon Yolanda – the strongest typhoon…

Staff Working Bee, Scottsdale Reserve, NSW

The third Jord Foundation (JET) roadshow was closer to home, just a 4 hour drive southwest of Sydney, to Scottsdale, a 1,300 hectare Bush Heritage property nestled on the banks of the Murrumbidgee…

Single lift paste back-fill filter installed

Jord has continued to support the mining industry’s drive towards sustainable tailings management

Can-Do Attitude: The Secret To 50 Years Of Business

Since its inception in 1972, Jord has grown and changed to meet the needs of its clients and has pursued innovation to deliver more value, efficiencies, and sustainability.

Jord’s Influencing Without Authority Program

As part of Jord's People Strategy, we are dedicated to enhancing capability and boosting engagement within our teams.

Overcoming sub-zero temperatures for dry cooling solutions

Our Senior Sales Manager discusses why sub-zero air coolers and condensers are the most difficult to design for reliable performance over the long term.

Celebrating a Milestone in Marine Conservation

Conservation International,Foundation,Bintan Marine Park

Jord proudly supports the ongoing development of the East Bintan Marine Protected Area (MPA).

Jord’s Latest Can Do Award Winners September 2025

This quarter, we honour those whose hard work, versatility, and commitment truly embody the Jord Can Do spirit.