O&G TOPSIDES NL1042 Compelling design extends life of ageing gas fields

Dubbed SHARP, or Southern Hub Area Rationalisation project, Jord’s task is to replace redundant compression equipment from the Leman and Indefatigable fields – developed some 50 years ago – with a single set of low pressure compression equipment that will serve both fields.

The project has two main work scopes. A brownfield element will simplify existing manned hubs into unmanned platforms and a greenfield element will involve conversion of a jack up rig into a new compression platform.

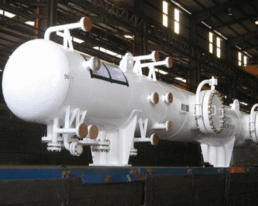

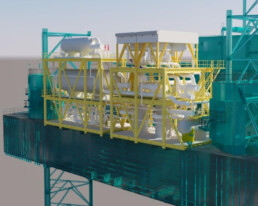

Jord’s scope entails two modules on the jack up rig, designed to separate, compress and export 100 MMSCFD of natural gas. In the foreground is a 250 ton gas compression module. Behind it sits a 270 ton slug catcher module. A third 220 ton pig launcher module forms part of the brownfield scope. Various smaller modules complete the scope of supply. These include chemical injection, fuel gas and produced water treatment.

O&G FT&C C6562 & C6774 Offshore mercury removal & gas separation modules

This project presented challenges from the start, not least of which was the precious little space available on the offshore gas platform to accommodate the fixed plant, and to make things more difficult deck space was also needed above the plant to allow for mercury catalyst change-out.

In addition to this mercury removal module, Jord also delivered a dry gas filtration module to the platform.

O&G DC C7539 Rebuilding Iraqi oil fields

Jord’s scope on this project comprised 11 process modules associated with fuel gas treatment for a 150MW power plant being constructed on the massive Halfaya oil field. There are five gas treatment modules, a condensate pre-heat module and six associated PSV skids.

O&G FTC C7513 Fast track fuel gas conditioning modules for Oman

Two of the modules were for a gas turbine generator service. The others serviced gas compressors. The customer needed these in a hurry and sought any and all ideas to achieve this.

Jord decided upon a common plot-space and mechanical design for both services, and met the design duty by using different set points. This enabled early procurement of components and together with some other initiatives, 8 weeks were shaved off the expected delivery program. A common design also aided plant operability and component inter-changeability between the four modules.

POWER FTC JEN1002 Two weeks for two fuel gas modules

A European gas turbine manufacturer was late on a delivery and was hard pressed to recover the situation. Under enormous time pressure, Jord helped them to design the module to some tricky site requirements.

Working around the clock, Jord assembled, tested and delivered the two units in a very short time – just two weeks from receipt of air-freighted free-issue components.

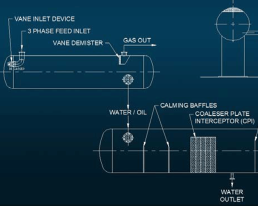

SERVICE S03 Inlet 3‐phase Separator debottlenecking

The platform had limited plot space, a constraint to available headroom, a limitation of 15 tonnes to all offshore lifts and no additional power available for increased pump capacity. These constraints prevented the replacement of the existing separator with a larger vessel.

- The bottleneck to production was resolved enabling the platform to attain the required higher production

- Capital cost was minimized through design of a solution that overcame the significant constraints of plot space, headroom, lift capacity and

- Disruption to platform production was minimized and client achieved maximized return on investment