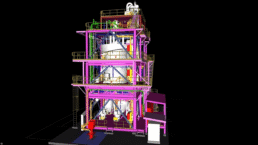

A partnership between Jord International, Aeris Resources and the NSW Regional Government is financing the installation of the first industrial-scale NovaCell™ Coarse Particle Flotation (CPF) Demonstration Plant. Located at the Tritton Copper Mine in NSW, Australia, the project is advancing this innovative flotation technology for coarse gangue rejection and pre-concentration.

The turnkey 85 (dry) tph plant, designed and delivered by Jord, will be integrated into the mine’s main operating circuit. Its design incorporates full-scale core components within a multi-downcomer system, providing a robust test for the technology viability. Sherwin Morgan, Technology Manager for NovaCell™ at Jord, stated, “The installation at Tritton represents a significant advancement in the NovaCell™’s technology readiness level. The successful operation of this plant will confirm the suitability of the technology at industrial scale for coarse gangue rejection.”

This demonstration project is also the world’s first installation of a CPF technology that operates without the requirement for upfront de-sliming. By processing the cyclone feed stream and handling both coarse and fine particles simultaneously within the NovaCell™ , the project validates a simplified flowsheet. Mr. Morgan emphasised this point, noting, “This project is exciting for the mining industry as it represents a simplification of future CPF circuits,” a development that promises to reduce both capital and operational costs for future mineral processing plants.

Aeris Resources’ copper mine in Australia (NSW), Tritton Operations, uses a “hub-and-spoke” model for delivery of ore from various sources to a central processing hub. This model offers the opportunity to leverage a portfolio of small to mid-sized regional (remote) copper resources as feed sources. One of the challenges with mining remote ore bodies is the additional transportation costs to the mill, requiring higher mining cutoff grades to offset these additional costs which ultimately reduce the mining inventory.

To fully realise the resource potential within remote resources, a near-mine ore pre-concentration capability is required to allow efficient and cost-effective upgrading of mined ore feed. At the heart of the modular / relocatable ore pre-concentration facility is the NovaCell™ , with its ability to process coarse ground ores and simultaneously and efficiently recover both coarse and fine minerals allowing savings in power, water and surface footprint. It also offers the opportunity to reduce the cost of tailings backhaul from the mill for use as pastefill, further enhancing the value equation.

The NovaCell™ technology could make a significant impact to Tritton’s future, facilitating the exploitation of remote resources and extending the life of the operation.

The success of NovaCell™ technology is also being demonstrated in other regions. A recent pilot trial at the Mantos Blancos mine in Antofagasta, Chile, has been successfully completed, with results to be presented by Capstone Copper at the Flotation ’25 conference in Cape Town, South Africa. Brandon Akerstrom, Director of Metallurgy at Capstone Copper, stated, “The NovaCell™ offers a distinct advantage by recovering valuable minerals across the entire particle size distribution generated by our existing comminution circuits. Moreover, it requires smaller downstream infrastructure to produce a marketable concentrate, significantly reducing capital expenditure compared to other CPF technologies we have assessed.” The positive results have promoted an economic study of a significantly larger-scale NovaCell™ plant at Mantos Blancos for a tailing scavenging duty. Confirming the core advantage of the technology, Mr. Morgan noted, “For Mantos Blancos, the NovaCell™ plant would also be installed without the need for an upfront de-slime circuit,” underscoring the simplicity of the NovaCell™ system.

Other News

Aminpro Exclusive Testing Partner NovaCell Chile

Aminpro, a leading metallurgical testing and consulting firm, is proud to announce its designation as the exclusive testing partner for Jord International’s groundbreaking NovaCellTM flotation…

Nurturing the Night Parrot

An arid patch of ground some 1,500 km north-west of Brisbane hit global headlines in 2013, with the exciting re-discovery of the Night Parrot, a nocturnal ground dwelling parrot previously thought…

Searching for Planigals

This fourth instalment of Jord’s annual Bush Heritage weekend involved 19 of us flying to its 60,000 hectare Carnarvon Reserve in central Queensland.