Jord Appoints Matthew Marinovich as Head of Energy

Jord International is delighted to announce the appointment of Matthew Marinovich as Head of Energy.

Matt joins Jord with more than 20 years of experience in the chemical, equipment, and industrial services sectors, bringing deep expertise in gas processing and modular LNG systems. He has successfully led major energy and industrial projects across the Asia Pacific region and internationally, partnering with clients in oil & gas, mining, power generation, and renewables.

His track record spans large-scale solutions across a wide range of technologies, from traditional gas processing to emerging energy markets, including hydrogen, carbon capture and storage (CCS), and energy storage.

Matt holds a Bachelor of Science (Chemistry, Hons) from the University of Western Australia and an MBA from Curtin Graduate School of Business.

Renowned for fostering high-performing teams built on trust, support, and accountability, Matt’s leadership will play a key role as Jord continues to deliver innovative solutions and expand into new opportunities in the global energy transition.

We’re excited to welcome Matt to the Jord team.

Jord opens office in Denver, USA

Jord International (Jord) is proud to open its new office in Denver, Colorado. Building on the firm’s 50-year history serving the global energy and resource sectors, the new office extends Jord’s support for the sectors’ transition to reliable, affordable and sustainable energy.

General Manager – Americas, Oliver Whatnall says Jord’s permanent home in the U.S. will provide greater service and responsiveness to its customers throughout the Americas.

“Jord recognises the critical role the two American continents play in the global energy transition. We’re collaborating with a growing family of partners here to pioneer innovative technologies that drive down critical mineral production costs, efficiently and sustainably,” said Mr Whatnall.

Jord’s global collaborations have led to several innovative technologies, including Viper, XtractOre and NovaCell™. Viper revolutionises tailings filtration, offering a simple, scalable and cost-effective solution. XtractOre recovers valuable minerals currently lost in tailing streams. NovaCell™ is a step-change in flotation for broad-based critical minerals processing, recovering both coarse and fine particles in one device, using less water and substantially less energy than conventional approaches.

Jord looks forward to working with its partners through and beyond the energy transition.

Pictured: Oliver Whatnall, Jord General Manager – Americas

Address: 250 Fillmore Street, Suite 150, Denver, CO 80206

Phone: +1 720 869 7610

Click here to email

About Jord International:

Jord Group designs, manufactures, commissions and services custom process plant and systems. From its Australian headquarters, Jord has delivered $5 billion of bespoke plant and systems to over 130 countries around the world, helping to make the energy and resource sectors ever more sustainable. Visit www.jord.com for more information.

Jord Appoints Claire Jelbart as Head of Legal

Jord International is pleased to announce the appointment of Claire Jelbart as our new Head of Legal.

Claire is a highly experienced executive leader, lawyer, and governance professional, bringing more than 20 years of experience in major projects and M&A across renewable energy, natural gas, LNG, mining, power, and infrastructure sectors.

With deep expertise in legal and commercial matters and a strong focus on regulatory excellence, Claire is known for her inclusive leadership style and ability to build trusted relationships with stakeholders. She has worked extensively across the Asia-Pacific region, including Japan, Taipei, and Port Moresby, gaining valuable cross-cultural insight and international business acumen.

Claire holds a Bachelor of Laws (Hons) and a Bachelor of Asian Studies (Mandarin) from the Australian National University, as well as additional qualifications in finance, corporate governance, and risk management.

Her strategic mindset, global perspective, and dedication to sustainable progress make Claire a tremendous addition to Jord’s leadership team as we continue to expand our global footprint and pursue our commitment to responsible, innovative growth.

Japan’s ever-expanding renewable energy drive

Jord is delighted to confirm its participation in the Wakayama Gobo Biomass Power Plant, located 120 km south of Osaka, Japan. Jord’s role is to design and construct the air-cooled vacuum steam condensing system (ACC) as part of the overall plant being built by Toyo Engineering Corporation. The plant will use wood pellets and agricultural byproduct as feedstock, to generate 50MW of power. Enough power to cater to 110,000 Japanese households a year.

Japan is investing in ways to match a 4% year-on-year growth in energy demand with reducing its reliance on fossil fuels. In 2022, Japan’s renewable energy output increased by 11.7 percent, driven primarily by solar power and biomass generation.

Jord’s ACC condenses the steam exhaust of the power plant’s steam turbine.

JordProxa selected for Vulcan Energy’s Lionheart Project

JordProxa has been selected by Vulcan Energy Resources (ASX: VUL, FSE: VUL) as the technology and equipment partner for the lithium purification, concentration, and conversion processes in Vulcan’s flagship Phase One Lionheart Project in Germany.

The Lionheart Project aims to establish Europe’s first fully domestic and sustainable lithium value chain, supporting the transition to clean energy and electric mobility across the continent.

JordProxa will deliver an integrated scope of advanced process technologies designed to transform lithium-rich eluates into high-purity lithium hydroxide monohydrate (LHM) suitable for use in electric vehicle batteries. The project will leverage JordProxa’s global expertise in crystallisation, evaporation, and water purification systems for the production of ultra-pure battery chemicals.

Vulcan Energy’s Managing Director and CEO, Cris Moreno, said, “The signing of this contract builds on our established partnership with JordProxa, a company which shares Vulcan’s commitment to excellence, innovation, and sustainability. JordProxa is a leading company in purification and concentration of battery- grade materials, and we are delighted to be using this world-class experience to deliver our flagship Phase One Lionheart project. We’re thrilled to be working alongside the exceptional JordProxa team as we progress towards construction of the Project, which will deliver Europe’s first fully domestic and sustainable lithium value chain.”

Paul Browne, Managing Director of JordProxa, commented, “Working alongside Vulcan on this journey has been truly rewarding. Our partnership is strengthened by open collaboration, shared purpose, and a genuine commitment to advancing sustainable lithium production in Europe.”

Sales Director at JordProxa, Nipen Shah, added, “It’s been a remarkable journey — from concept to contract. I am proud of the teams who demonstrated focus, commitment, and professionalism, and helped position JordProxa as a trusted partner in the energy transition.”

With more than 50 years of experience across diverse industries, JordProxa delivers modular, cost-effective solutions that integrate the latest advances in process technology. The company provides complete lifecycle support, from R&D and testing to project execution and aftermarket services, helping clients meet the world’s growing demand for sustainable, high-performance materials.

Reflecting on our 51st year of operations

Jord CEO Angus Holden says, “It gives me great pleasure to report a record year for Jord with $320 million of revenue.”

Watch a short video report:

In our 51st year of operations, our team expanded, we opened a new office in Denver, and we advanced some exciting new technologies.

Project highlights included:

- Vacuum steam condensers for a biomass waste to energy plant in Japan.

- Compressor balance of plant modules for a carbon capture projects in the USA and Australia.

- Zero liquid discharge (ZLD) effluent treatment plant for an EV battery recycling plant in Rochester, New York.

- Accessory modules supporting GE’s latest generation 9HA gas turbine technology for a 6,500MW power plant in Taiwan.

- Clean air scrubbing system for a zinc smelter in Australia.

- Topside modules weighing over 10,000 tons for an FPSO in Brazil including the first combined cycle power plant to be installed on an FPSO.

- Cooling water modules for an LNG plant in Plaquamine, USA.

- Viper and NovaCell™ demonstration plants for minerals beneficiation process plants in Chile and the USA.

About Jord

The next 30 years will see massive energy investment as the world shifts from the fuels of the 20th century to meet the renewable energy needs of the 21st, and safeguard the children of the 22nd. Jord is pioneering new technologies required for this transition and improving our existing technologies to minimise their impact.

Our role is threefold:

- design and construct process plant for traditional resource and energy sectors essential to power the transition.

- focus on technology innovations that deliver critical minerals and power new energy solutions in an efficient, cost-effective and sustainable manner.

- ensure our Aftermarket solutions allow existing process plant to run more efficiently, thereby lowering emissions and extending plant life.

We have learned a lot in 50 years. It’s yours to go.

Contact

For more information, visit www.jord.com or phone +61 2 8425 1500.

Jord recognised by GE Vernova with Supplier Partnership Award

Jord is proud to be recognised by GE Vernova with their Supplier Partnership Award for Accountability.

The award acknowledges Jord Energy’s contribution to the challenging Greemu brownfield project in China, where GE Vernova entrusted our team to deliver a critical skid within an exceptionally tight timeframe. Demonstrating outstanding commitment and collaboration, Jord successfully completed the delivery one month ahead of schedule while maintaining the highest standards of quality.

We extend our sincere thanks to the GE CMU team for their trust and partnership, and to Mr. Guo Jian, President of GE Vernova China, for acknowledging our efforts.

This recognition is a testament to the dedication, teamwork and accountability of our people across Jord, who consistently deliver excellence under pressure.

JordProxa and Vulcan Partnership

JordProxa and Vulcan Energie Ressourcen GmbH (Vulcan) and have entered into a Memorandum of Understanding (MoU) for the technology and process components for the Lithium Extraction and Central Lithium Plants of Vulcan’s Phase One integrated renewable energy and ZERO CARBON LITHIUM™ Project (the Project).

The partnership between Vulcan and JordProxa as the selected technology partner is geared toward the joint objective of delivering Vulcan’s Phase One Project on time with improved cost performance and optimisation for the lithium process portion of the project development.

Leveraging JordProxa’s expertise in providing solutions for producing high purity battery grade products by integrating crystallisation, evaporation, water treatment technologies, the intent of the MoU is to enhance project processes and production, streamline delivery times, and optimise Vulcan’s project costs. Additionally, this MoU will facilitate early engagement with Vulcan’s EPCM contractor and the Main Electrical and Automation Contractor to clarify scope definition, boundary limits, design principles, standards, and interfaces. Design optimisation will be achieved by integrating JordProxa’s experience and utilising the capability, data and knowledge from Vulcan’s current pilot and optimisation plants.

Working closely with Vulcan’s team in Germany, JordProxa will optimise the design basis and develop pricing proposals, project execution plans, and an interface management plan.

Beyond project completion, JordProxa’s commitment is intended to extend to operational support and continuous performance improvement initiatives throughout the plant’s lifecycle. This long-term commitment would ensure that Vulcan can rely on JordProxa’s support and expertise even after the Project is completed.

Vulcan MD and CEO, Cris Moreno stated, “I’m confident this MoU marks the beginning of a promising long-term partnership between Vulcan and JordProxa. We are delighted to join forces with JordProxa to deliver cutting-edge water processing, crystallisation and evaporation systems for Phase One of our integrated renewable energy and ZERO CARBON LITHIUM™ Project and beyond, underscoring our mutual dedication to innovation and sustainability.”

Director of JordProxa, Angus Holden stated, “Vulcan’s ZERO CARBON LITHIUM™ Project offers a breakthrough opportunity in sustainable lithium production. JordProxa’s MoU with Vulcan enables our joint teams to work as partners towards the common goal of sustainable lithium. We look forward to supporting Vulcan in realising this milestone project”.

JordProxa, is a leader in custom end-to-end battery minerals processing, crystallisation and evaporation plant and systems, playing a key role in meeting the challenges of high purity, sustainability, and value to meet the increasing demand for lithium-ion and other battery metals. JordProxa has over 250 project references globally including major battery grade projects for blue chip clients in Finland, Australia, Latin America and Canada.

Upon completion of the MoU scope, Vulcan and JordProxa aim to advance towards a definitive agreement for the execution of Vulcan’s Phase One Lithium Extraction and Central Lithium Plants of the ZERO CARBON LITHIUM™ and Renewable Energy Project.

About Vulcan

Founded in 2018, Vulcan’s purpose is to empower a carbon neutral future, through the co-production of lithium, heat and renewable energy from geothermal brine. Vulcan is focused on delivering the world’s first integrated renewable energy and ZERO CARBON LITHIUM™ Project. By adapting existing technologies to efficiently extract lithium from geothermal brine, Vulcan aims to deliver a local source of sustainable lithium for Europe, built around a carbon neutral strategy with exclusion of fossil fuels. Already an operational renewable energy producer, Vulcan will also provide renewable electricity and heat to local communities. Vulcan’s combined geothermal energy and lithium resource is the largest in Europe, with licence areas focused on the Upper Rhine Valley, Germany. Strategically placed in the heart of the European electric vehicle market to decarbonise the supply chain, Vulcan is rapidly advancing the ZERO CARBON LITHIUM™ Project to target timely market entry, with the ability to expand to meet the unprecedented demand that is building in the European markets. Guided by our Values of Climate Champion, Determined and Inspiring, and united by a passion for the environment and leveraging scientific solutions, Vulcan has a unique, world leading scientific and commercial team in the fields of lithium chemicals and geothermal renewable energy. Vulcan is committed to partnering with organisations that share its decarbonisation ambitions and has binding lithium offtake agreements with some of the largest cathode, battery, and automakers in the world. As a motivated disruptor, Vulcan aims to leverage its multidisciplinary expert team, leading geothermal technology and position in the European EV supply chain to be a global leader in producing carbon neutral lithium. Vulcan aims to be the largest, most preferred, strategic supplier of lithium chemicals and renewable power and heating from Europe, for Europe; to empower a carbon neutral future.

About JordProxa

JordProxa delivers custom engineered solutions to produce a wide range of ultra-pure battery chemicals by integrating advanced water treatment, evaporation and crystallization technologies. Our experience, spanning over 45 years in diverse industries enables us to offer cost effective and robust solutions that incorporate the latest advances in technology.

Head quartered in Sydney, Australia, JordProxa operates throughout Europe, North & South America, Middle East, Africa and Southeast Asia. It offers the complete range of capabilities and services from project inception to completion, including R&D, testing, on-going operational support and aftermarket support.

Through on-going research and development, both in-house and through tertiary academic and research institutions, the company is able to continuously meet and exceed the ever-increasing purity needs of lithium-ion batteries and other energy metals,

We leverage an established network of fabrication alliances and decades of experience with modular plant design. This allows us to deliver key plant assemblies that are extensively tested and proven in the workshop before they are dispatched and installed on site. This helps us optimise project delivery time whilst minimising the project risk.

For any enquiries, please contact Nipen Shah on +61 2 8425 1500 or email info@jordproxa.com

NovaCell™ implemented at Industrial scale

A partnership between Jord International, Aeris Resources and the NSW Regional Government is financing the installation of the first industrial-scale NovaCell™ Coarse Particle Flotation (CPF) Demonstration Plant. Located at the Tritton Copper Mine in NSW, Australia, the project is advancing this innovative flotation technology for coarse gangue rejection and pre-concentration.

The turnkey 85 (dry) tph plant, designed and delivered by Jord, will be integrated into the mine’s main operating circuit. Its design incorporates full-scale core components within a multi-downcomer system, providing a robust test for the technology viability. Sherwin Morgan, Technology Manager for NovaCell™ at Jord, stated, “The installation at Tritton represents a significant advancement in the NovaCell™’s technology readiness level. The successful operation of this plant will confirm the suitability of the technology at industrial scale for coarse gangue rejection.”

This demonstration project is also the world’s first installation of a CPF technology that operates without the requirement for upfront de-sliming. By processing the cyclone feed stream and handling both coarse and fine particles simultaneously within the NovaCell™ , the project validates a simplified flowsheet. Mr. Morgan emphasised this point, noting, “This project is exciting for the mining industry as it represents a simplification of future CPF circuits,” a development that promises to reduce both capital and operational costs for future mineral processing plants.

Aeris Resources’ copper mine in Australia (NSW), Tritton Operations, uses a “hub-and-spoke” model for delivery of ore from various sources to a central processing hub. This model offers the opportunity to leverage a portfolio of small to mid-sized regional (remote) copper resources as feed sources. One of the challenges with mining remote ore bodies is the additional transportation costs to the mill, requiring higher mining cutoff grades to offset these additional costs which ultimately reduce the mining inventory.

To fully realise the resource potential within remote resources, a near-mine ore pre-concentration capability is required to allow efficient and cost-effective upgrading of mined ore feed. At the heart of the modular / relocatable ore pre-concentration facility is the NovaCell™ , with its ability to process coarse ground ores and simultaneously and efficiently recover both coarse and fine minerals allowing savings in power, water and surface footprint. It also offers the opportunity to reduce the cost of tailings backhaul from the mill for use as pastefill, further enhancing the value equation.

The NovaCell™ technology could make a significant impact to Tritton’s future, facilitating the exploitation of remote resources and extending the life of the operation.

The success of NovaCell™ technology is also being demonstrated in other regions. A recent pilot trial at the Mantos Blancos mine in Antofagasta, Chile, has been successfully completed, with results to be presented by Capstone Copper at the Flotation ’25 conference in Cape Town, South Africa. Brandon Akerstrom, Director of Metallurgy at Capstone Copper, stated, “The NovaCell™ offers a distinct advantage by recovering valuable minerals across the entire particle size distribution generated by our existing comminution circuits. Moreover, it requires smaller downstream infrastructure to produce a marketable concentrate, significantly reducing capital expenditure compared to other CPF technologies we have assessed.” The positive results have promoted an economic study of a significantly larger-scale NovaCell™ plant at Mantos Blancos for a tailing scavenging duty. Confirming the core advantage of the technology, Mr. Morgan noted, “For Mantos Blancos, the NovaCell™ plant would also be installed without the need for an upfront de-slime circuit,” underscoring the simplicity of the NovaCell™ system.

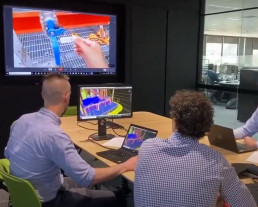

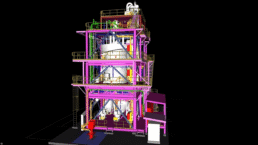

Video link remote inspections

When the COVID pandemic was declared, our JordProxa joint venture was building crystalliser modules in China and the project teams included personnel in South Africa, India and Australia. Remote inspections helped us to overcome the challenge of having geographically dispersed teams and international clients.

A key benefit we discovered was that remote inspections allow us to refer to all the available engineering information in the office – such as the 3D model and P&IDs – at the same time that we are inspecting the equipment, resulting in more thorough collaborative reviews in real time. The narrow view through the lens of a camera also forces all participants to focus on the same small details for attention and more efficient decision-making.

We undertake remote inspections by video link, which involves a local Quality Control inspector moving a camera very methodically around the modules in the fabrication workshop. Using P&IDs as a basis, we check all the details piece by piece.

Watch to learn more from our joint venture team delivering crystallisers and evaporators for battery metals producers